Page 9 - Oil & Gas Final

P. 9

Technical features

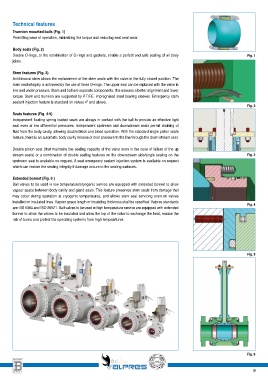

Trunnion mounted balls (Fig. 1)

Permitting ease of operation, minimizing the torque and reducing seat seal wear.

Body seals (Fig. 2)

Double O-rings, or the combination of O-rings and gaskets, enable a perfect and safe sealing of all body Fig. 1

joints.

Stem features (Fig. 3)

Antiblowout stem allows the replacement of the stem seals with the valve in the fully closed position. The

stem seal integrity is achieved by the use of three O-rings. The upper seal can be replaced with the valve in

line and under pressure. Stem and ball are separate components; this ensures a better alignment and lower

torque. Stem and trunnion are supported by P.T.F.E. impregnated steel bearing sleeves. Emergency stem

sealant injection feature is standard on valves 4” and above.

Fig. 2

Seats features (Fig. 4-5)

Independent floating spring loaded seats are always in contact with the ball to provide an effective tight

seal even at low differential pressures. Independent upstream and downstream seats permit draining of

fluid from the body cavity, allowing double block and bleed operation. With the standard single piston seats

feature, there is an automatic body cavity release of over pressure to the line through the down stream seat.

Double piston seat (that maintains the sealing capacity of the valve even in the case of failure of the up

stream seats) or a combination of double sealing features on the downstream side/single sealing on the Fig. 3

upstream seat is available on request. A seat emergency sealant injection system is available on request

which can restore the sealing integrity if damage occurs to the sealing surfaces.

Extended bonnet (Fig. 6 )

Ball valves to be used in low temperature/cryogenic service are equipped with extended bonnet to allow

vapour space between body cavity and gland seals. This feature preserves stem seals from damage that

may occur during operation at cryogenic temperatures, and allows stem seal servicing even on valves

installed on insulated lines. Vapour space length or insulating thickness shall be specified. Valpres standards

Fig. 4

are: BS 6364 and ISO 28921. Ball valves to be used in high temperature service are equipped with extended

bonnet to allow the valves to be insulated and allow the top of the valve to exchange the heat, reduce the

risk of burns and protect the operating systems from high tempeartures.

Fig. 5

Fig. 6

9